CONNECT YOUR BUSINESS WITH HEALTHCARE MANUFACTURING IN LATIN AMERICA AND THE CARIBBEAN

NearMed Supply connects US healthcare companies with vetted manufacturers in Latin America and the Caribbean to escape rising tariffs and long lead times.

Up to 65% Faster Production

Avoid China Tariffs

FDA Ready Facilities

The Hidden Costs of Overseas Manufacturing

Healthcare companies face critical challenges with traditional overseas production:

- Unpredictable tariffs cutting into profit margins

- 3-4 month lead times causing inventory disruptions

- Quality issues that compromise patient safety

- Communication barriers across multiple time zones

- Escalating logistics costs and supply chain vulnerabilities

These factors don't just impact your bottom line—they put your entire business at risk in today's volatile market.

Nearshore Manufacturing: Closer, Faster, Better

Our network of Latin American manufacturers delivers a strategic alternative to traditional overseas production with measurable advantages.

Shorter Lead Times

Nearshore partners reduce shipping and customs delays, getting your products to market weeks sooner than overseas options.

Real Time Coordination

Get fast, same day responses from local partners in your time zone, keeping coordination simple and efficient.

Lower Total Cost

Save on freight, tariffs, and brokers. Nearshoring can lower your total landed costs by as much as 30% for many products.*

U.S. Level Standards

We connect you with FDA-registered, ISO 13485, or GMP-certified facilities. Ensuring full compliance without hidden risks.

*Savings depend on product, order volume, and shipping choices.

Nearshoring vs. Traditional Overseas Manufacturing

See how our nearshore solution compares to traditional overseas manufacturing:

Feature | Traditional Overseas | NearMed Nearshoring |

|---|---|---|

Lead Times | 90-120 days ⨯ | 30-45 days ✓ |

Tariffs | Up to 25% additional cost ⨯ | 0-5% under trade agreements ✓ |

Shipping Costs | High & volatile ⨯ | 40-60% lower ✓ |

Time Zone | 12+ hour difference ⨯ | 0-3 hour difference ✓ |

Quality Control | Difficult, costly visits ⨯ | Easy facility access ✓ |

The Nearshore Advantage

- While the chart highlights key differences in lead times, tariffs, shipping costs, time zones, and quality control, there’s more to consider when choosing nearshoring.

- With NearMed, products move faster from production to market, cutting weeks off traditional timelines. This speed isn’t just about logistics; it helps you respond to market demands and inventory shifts without the stress of 90-120 day delays.

- You also get peace of mind knowing your suppliers are close, accessible, and easy to communicate with. No 12-hour time zone gaps or language barriers slowing down decisions. Need to visit a facility? It's a short trip, not a costly international venture.

- We go further with compliance oversight. Every partner meets FDA registration, ISO certifications, and undergoes regular audits; giving you confidence in product quality without surprises.

- NearMed reduces your exposure to global risks like unstable tariffs, freight disruptions, and geopolitical shifts. Our Latin American partnerships offer a stable, efficient alternative that protects your margins and supply chain.

Choose nearshoring. Stay agile. Stay competitive.

Specialized Manufacturing for Your Healthcare Needs

Our manufacturer network specializes in a wide range of healthcare products:

Nitrile Gloves & PPE

FDA-compliant examination gloves, masks, gowns, and protective equipment manufactured to strict quality standards.

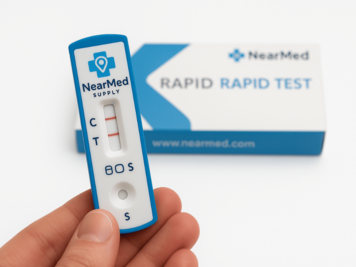

At-Home Test Kits

Diagnostic test kits with reliable components, clear instructions, and accurate results for various health conditions.

OTC Medical Devices

Consumer-grade medical devices from trusted manufacturers following ISO 13485 certification standards.

Supplements

Private label supplements capsules, powders, and gummies made in FDA registered, cGMP-certified U.S. facilities for export.

Custom Packaging

Medical-grade packaging solutions designed for your specific product requirements with sustainable materials.

Simple Three-Step Process

Our streamlined approach makes connecting with qualified manufacturers effortless:

1

Submit Requirements

Complete our brief qualification form with your product specifications, quantities, and timelines.

2

Review Matches

Within 5 business days, receive detailed profiles of pre-vetted manufacturers that meet your exact needs.

3

Launch Production

Select your preferred partner and begin manufacturing with our ongoing support and quality oversight.

NearMed's Quality Assurance Framework

1. Pre-Vetting

All suppliers complete our 27-point check: licensing, certifications, financials, references.

2. Certification Verification

We confirm FDA registration, ISO 13485, or GMP certification based on product type.

3. Sample Evaluation

You receive physical samples or batch history before contracting. Optional lab testing support available.

4. Site Visit or Video Audit

In-person inspections or remote video walkthroughs ensure production transparency.

5. Ongoing Performance Monitoring

We track fulfillment timelines, defect rates, and customer feedback across suppliers.

Frequently Asked Questions

Q: What types of products can you help source?

We currently focus on healthcare-specific items such as PPE, OTC products, lab supplies, and packaging components. Custom sourcing is also available on request.

How quickly can I start production?

Production timelines vary based on product complexity and supplier availability, but many clients launch within 2–4 weeks of initial inquiry.

Q: What quality checks do you perform?

All partners are screened through our 27-point verification process. We review certifications (e.g., FDA, ISO, GMP), facility audits, and past production quality. You’ll receive a QA summary before onboarding.

Do you have minimum order quantities?

MOQs vary product and manufacturer. Our network includes partners for both high-volume production and smaller specialty runs. During our matching process, we align your volume requirements with appropriate manufacturers and can often consolidate. Orders across multiple clients for specialized components.

Q: What’s the pricing model?

We typically operate on a sourcing fee, depending on your volume and needs. Reach out for a custom quote.

Q: What cost savings can I expect?

Nearshoring can reduce total landed costs by 10–30% depending on the product category, freight route, and customs savings. We'll help you assess where the biggest gains can be unlocked. All cost figures are estimates and subject to variability based on order size, product type, and supplier availability.

Client Success Stories

"We switched to NearMed after months of delays with our overseas supplier. Not only did we get our order 8 weeks faster, but the product quality actually improved."

Nutraceutical Brand

Texas

"NearMed helped us secure a reliable PPE supplier in the Caribbean. No shipping delays, no customs issues, just consistent, FDA compliant deliveries."

Hospital Procurement Director

Florida

"By nearshoring with NearMed, we saved 18% on logistics and avoided the 25% tariff hike that would’ve crushed our bottom line."

Veterinary Supply Company

Illinois

"Our diagnostics line was stuck in customs every other month. NearMed solved that by connecting us with a certified LATAM partner, we’ve had zero interruptions since."

Lab Testing Company

New York

Start Sourcing Smarter Today

Get connected with trusted manufacturers in Latin America and shorten your supply chain without compromising quality.